In spring of 2020, thousands of scientific labs across several continents shut down. What was deemed “non-essential” research was ramped down and/or paused in an effort to stop the spread of the coronavirus, and in some cases direct resources to Covid-19 research instead. Speaking with scientist friends and interlocutors in both Brazil, where I was carrying out research, and the US, where I’m from and have worked in labs myself, there was much discussion about what work to do in the meantime to continue progressing theses, dissertations, and research projects—in other words, to maintain productivity. On Twitter, numerous threads under the hashtag #phdlife offered advice and encouragement to “scientists without a lab,” as one graphic put it:

Source: https://twitter.com/ZJAyres/status/1239983524259737606

At one point, although not immediately, I realized my field notes were thus still circling around an enduring theme from before the pandemic, even amid the drastic changes in my scientist interlocutors’ daily lives—productivity. I research how scientists and industry actors in São Paulo make biofuels, bioplastics, and other sugar-based renewables from sugarcane. The various ways that sugarcane productivity is measured, communicated, engineered, and otherwise made to matter is central in such efforts. Brazil has produced large volumes of sugarcane-based biofuels for almost half of a century now, but my interlocutors’ research seeks to increase the number of products that can be made with sugarcane, as well as increase the amount of sugar that can be extracted from sugarcane in order to improve production efficiency and thus sustainability. One way to increase the amount of extractable sugar is to improve the plant’s productivity.

In this post I analyze these two instances of productivity side by side—lab productivity and sugarcane productivity—not to imply they are equivalent, but to see how each assumes or enacts certain ideas about productivity that can in turn illuminate the work of productivity in the other. Specifically, these moments show that the use of a singular form of productivity (versus productivities, plural) belies other processes (of labor, work, sugar extraction—i.e., different kinds of productivity) that happen at the same time. Instead, by looking at productivities, we see that some narratives of change actually contain more continuities than immediately suggested, in the form of other productivities not recognized as such that aren’t necessarily changing.

This ultimately shapes how we might interpret broader narratives of production, such as that sugarcane is a sustainable alternative to oil in large part because scientists are “increasing its productivity.” What is happening when crops’ productivity is increased? What kind of change is this in our agricultural and production systems? What other kinds of productivity on the parts of scientists, agricultural laborers, and other actors does this require?

An analytical note

Scholars have long offered vital critiques of what, and who, counts as productive or not. Certain work has historically been obscured or devalued (care work, racialized work, gendered work); this has been highlighted and exacerbated amid the pandemic. In the context of scientific practices specifically, uncertain temporalities of work may constitute rather than interrupt productivity (Tousignant 2018). Here I take some small examples to elaborate on these critiques, particularly in contexts where productivity isn’t necessarily obscured or devalued yet still is not recognized as such, and also in exploring how such critiques might intersect with plant or agricultural research.

Juxtaposing the productivity of people and plants can push us to ask some interesting questions. What fundamental conceptions of work, productivism, and extraction seep into seemingly disconnected realms like plant biochemistry and the manual labor of scientific knowledge production? On the one hand, as STS scholars and anthropologists of science have long demonstrated, biological narratives are already social narratives. To say that productivity in sugarcane is unrelated to economic understandings of productivity perhaps risks reifying an objective, foundational materiality of biology (Paxson and Helmreich 2014). On the other hand, sugarcane production and plantations more broadly were central to the very emergence of capitalism, suggesting that the biological specificities of cane and other crops are more than incidental to understandings of labor (Mintz 1985; Besky 2013). Thus, I want to bring sugarcane into the same plane of analysis as productivism and vice versa, not merely proximate planes. Tracing some of these indirect connections between lab productivity and sugarcane productivity, in this way, might be a step toward understanding human/economic/plant productivity in a fuller way.

The work it takes to stop working in the lab

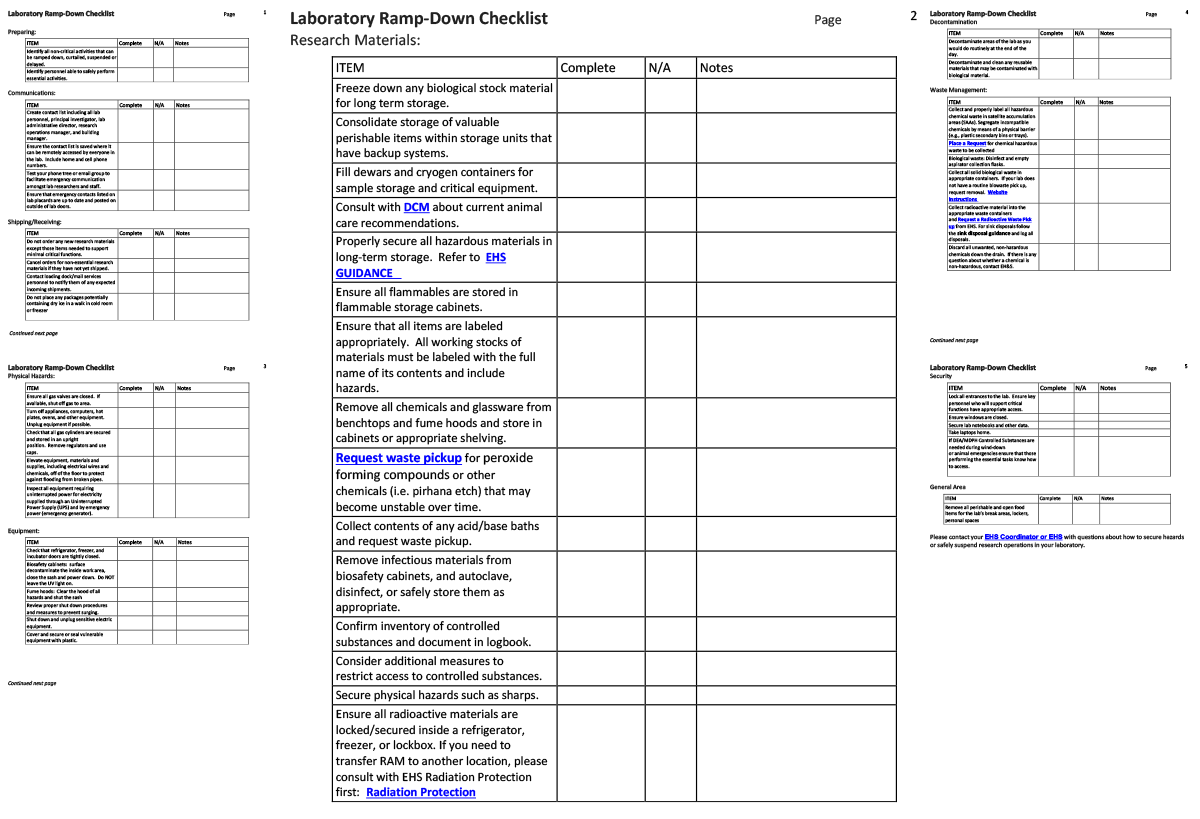

Around the middle of March 2020, I saw scientists on Twitter sharing a timely resource: a lab ramp-down checklist from a major US research institution. It was meant to help labs safely cease operations by identifying everything that needed to be done in order to do so. Soon such checklists were posted on many institutions’ websites. In US contexts the lists were very similar and seemingly derived from the same original checklist. (I wrote in my notes that this list seemed to be spreading fast like the virus itself.)

The list is several pages long and divided into ten categories: preparing, communicating, shipping/receiving, research materials, physical hazards, equipment, decontamination, waste management, security, and general area (Figure 1). Each category has from several to more than a dozen tasks, such as:

- test your phone tree

- cancel non-essential reoccurring orders

- freeze down biological stock materials for long-term storage

- consolidate valuable perishable items into freezers that have emergency power

- secure hazardous materials

- request hazardous waste pickup for compounds that might become unstable over time

- ensure gas valves are closed

- unplug equipment

- decontaminate and destroy infectious or living materials

- secure lab notebooks

Figure 1: A lab ramp-down checklist. [1]

Skimming through these checklists, I was struck by how much work it takes to stop working. These lists make evident the regular infrastructures—including both materials as well as labor—that keep labs running, and how turning off these infrastructures is not necessarily a simple switch. Through such lists, some materials’ own forms of agency becomes prominent, like hazardous reagents that remain active and resist the temporal restructuring of the ramp-down. Other materials can be frozen, scientists better able to control their temporalities. But freezing requires maintenance too, from ensuring there are back-up power sources to refilling liquid nitrogen tanks on a regular basis.

In sum, stopping requires activity and maintenance, although this doesn’t count as the same kind of scientific productivity. Scientists have been fully acknowledging this extra work, but at the same time, narratives of decreasing lab productivity shift the focus away from these other kinds of scientific productivities not typically conceived as such.

Finding new sugar in sugarcane—or the same sugar?

In recent decades, new kinds of scientific knowledge have created the potential to extract both new and more kinds of sugar from sugarcane, beyond just the syrupy juice pressed from the stalks that has been refined into sugar for centuries and processed into fuels in Brazil since the 1970s. These new kinds of sugars are instead found in stems and leaves and require biochemical knowledge for extraction because they’re molecularly “trapped” within a recalcitrant cell wall. Utilizing these trapped stem/leaf sugars is called second-generation (2G) biofuels and is framed as more sustainable through effectively increasing sugarcane’s yield/productivity. Seemingly, then, 2G is about finding new extractable sugar in stems and leaves, not only the stalk.

However, more longstanding agricultural practices and knowledge of sugarcane complicate this narrative of increasing productivity by finding new sugar. Specifically, sugarcane undergoes the physiological process of maturation, or ripening, in which sugars in the plant’s leaves change form and translocate to the stalk. Producers care about this process because once sugars are in the stalk, they can be extracted via conventional, first-generation (1G) methods. (2G biofuels are still mostly in demo phase.) Maturation happens “naturally” to a degree in response to drought and other environmental factors, but it can also be induced and increased by adding certain chemicals to the cane fields. As one Brazilian interlocutor put it, promoting maturation (by adding chemicals) or managing maturation (by harvesting at specific times in relation to rain) is about intervening in the plant’s vegetative rhythm to make a “richer” and more productive cane. Practices around maturation, then, had already brought sugarcane’s leaves (and leaf sugars) into the picture. In moving sugar from the leaves to the stalk, maturation enrolls the leaves as a fundamental site of the process.

Analyzing maturation in this way nuances narratives of 2G finding “new” sugar to increase the plant’s productivity. As a caveat, 2G potentially entails a much higher degree of extraction of these leaf sugars than maturation. Still, I think these small technical details about maturation and leaf sugars can open up questions. Having considered above the unexpected work it takes to stop working—those other kinds of scientific productivities sidelined by narratives of decreasing productivity—I wonder if 2G’s apparent increasing of productivity via new sugar could likewise be conceived as more of an alternative definition of existing cane productivity in the first place. 2G might not find new sugar per se, but simply extracts sugar before the sugar even needs to move, via maturation, to the stalks.

When increasing productivity is used in justifications of sustainability and new technologies like 2G, then, we might also need to ask what continuities in sugarcane productivity(ies) are there as well—what is 2G/sustainability sustaining and maintaining, and what (sugar) is indeed actually changing?

Taking lab and sugar productivities together

In the lab, discourses about the challenges of staying productive during shutdown exist simultaneously with all the other kinds of productive work required to be shut-down in the first place. When sugarcane is framed as increasingly sustainable as science makes it more and more productive, it’s worth asking further where this new sugar comes from and how new it really is.

I suggest that when we think about productivity, in a range of contexts, it can help to consider it as productivities: thinking about productivity in a singular sense belies the multiple other kinds of work happening in the meantime or historically. The examples I examine here show this is a different point than labor being obscured or devalued. In turn, a singular understanding productivity enables a linear narrative of change—in terms of either increases (sugar) or decreases (lab) in said productivity—which likewise masks other processes and even continuities happening at the same time.

References

Besky, Sarah. 2013. The Darjeeling Distinction: Labor and Justice on Fair-Trade Tea Plantations in India. Berkeley: University of California Press.

Mintz, Sidney. 1985. Sweetness and Power: The Place of Sugar in Modern History. New York: Penguin.

Paxson, Heather and Stefan Helmreich. 2014. “The Perils and Promises of Microbial Abundance: Novel Natures and Model Ecosystems, from Artisanal Cheese to Alien Seas.” Social Studies of Science 44(2): 165-193.

Tousignant, Noémi. 2018. Edges of Exposure: Toxicology and the Problem of Capacity in Postcolonial Senegal. Durham, NC: Duke University Press.

Note

[1] Extended text description for Figure 1. Page two of the document is highlighted to be read. The page is titled “Laboratory Ramp-Down Checklist” and contains a table with four headings: “Item,” “Complete,” “N/A,” and “Notes.” All of the columns except “Item” are empty. The list of items is pasted below.

- Freeze down any biological stock material for long term storage.

- Consolidate storage of valuable perishable items within storage units that have backup systems.

- Fill dewars and cryogen containers for sample storage and critical equipment.

- Consult with DCM about current animal care recommendations.

- Properly secure all hazardous materials in long-term storage. Refer to EHS GUIDANCE

- Ensure all flammables are stored in flammable storage cabinets.

- Ensure that all items are labeled appropriately. All working stocks of materials must be labeled with the full name of its contents and include hazards.

- Remove all chemicals and glassware from benchtops and fume hoods and store in cabinets or appropriate shelving.

- Request waste pickup for peroxide forming compounds or other chemicals (i.e. pirhana etch) that may become unstable over time.

- Collect contents of any acid/base baths and request waste pickup.

- Remove infectious materials from biosafety cabinets, and autoclave, disinfect, or safely store them as appropriate.

- Confirm inventory of controlled substances and document in logbook.

- Consider additional measures to restrict access to controlled substances.

- Secure physical hazards such as sharps.

- Ensure all radioactive materials are locked/secured inside a refrigerator, freezer, or lockbox. If you need to transfer RAM to another location, please consult with EHS Radiation Protection first: Radiation Protection.