Hundreds of tonnes of poisonous Styrene gas leaked out of the LG Polymers plant in Visakhapatnam, Andhra Pradesh on the 7th of May 2020, leaving 11 dead and others severely affected. Source: Wikimedia Commons

Under the Environment Protection Law in India, industries that process petrochemical-based products, such as styrene, require two levels of clearances—an Environmental Clearance (EC) from the Union Ministry of Environment, Forest and Climate Change (MoEF&CC) and a Consent to Operate (CTO) from the State Pollution Control Board (SPCB) which needs to be renewed every five years. As per the reports of the Center for Science and Environment, LG Polymers India had not adhered to rules at both these levels. The inquiry into the causes of the Vizag Gas leak that wreaked havoc in the lives of the denizens of the port city has made it clear that the industry has thrown to the winds any sense of responsibility by withholding crucial information whilst applying for the Environmental Clearance (EC) and Consent To Operate (CTO), thus subverting the regulatory framework to its advantage.

This evokes the question of how the industry evaded the ‘watchful eyes’ of regulatory bodies? Why, despite the protocols in place, did the management choose to ignore them? Why despite the plethora of laws, like the Hazardous Waste (management, handling, and trans-boundary movement) Rules (1989); Manufacture, Storage and Import of Hazardous Chemicals Rules (1989); and Chemical Accidents (Emergency, Planning, Preparedness, and Response) Rules (1996), enacted after the Bhopal gas tragedy, did this disaster happen?

The analysis so far, particularly the report of the high power committee appointed to look into the causes of the accident, is trying to look at the incident from a realist perspective, which cites certain technical, legal, and procedural lapses leading to the accident. However, to understand the complete anatomy of such disasters one also needs to look into the understandings of risk embedded in the regulatory procedures, which facilitate these lapses.

Protestors in Bhopal marching against Union Carbide and Dow Chemicals, the key stakeholders of the Union Carbide Plant in Bhopal, where one of the worst industrial accidents in history happened in 1984. Source: Iris Janssens- 32nd Anniversary of the Bhopal Disaster. Rallies and parades, in commemoration of the dead and as a protest for justice.

The high power committee report suggests that negligence on the part of the company workers was one of the key causes of the accident, besides technical causes such as poor maintenance of the plant and lack of proper safeguards. Such an assertion relegates responsibility to the domain of human error and averts the gaze from the structural deficiencies of the regulatory framework, and the dangers inherent in large and ‘high risk’ technical and industrial systems. It is relevant here to note that after examining a huge range of techniques and accidents, Perrow (1984) concluded that in complex technologies, such as nuclear power, such accidents are ‘normal’ or unpreventable. He argues that “because of their catastrophic character, it would be irresponsible even to introduce such technologies” (Zinn, 2009, p.11). However, in the aftermath of industrial disasters, not only are these risks talked down, lower-rung employees are often implicated, who serve as scapegoats for the mistakes on the part of other actors higher up the ladder, such as management of large corporations, bureaucrats involved in legal decision making, and scientific advisors. This, in turn, serves to undermine the failure of expertise and the delays caused by laws, or the very absence of assessment of long-term effects of hazardous chemicals.Though little is known about the nature of such hazardous compounds used in large scale industries and the effects of exposure to these chemicals, this non-knowledge is often downplayed, and the uncertainty is used to push the projects forward rather than deter their proceedings. The properties of Styrene gas which leaked from the LG plant in Vizag and the dangers posed by it were completely lost on the industry itself, as was in the case of the Methyl Iso-cyanate gas in Bhopal (Jasanoff, 2007). Thus, science, industry, and regulation are often at odds with one another at crucial junctures.

Government Accountability: Apportioning Blame, Discounting Responsibility

In the case of the Vizag gas leak, different institutions including the Andhra Pradesh (State) Pollution Control Board (APPCB) and the Ministry of Environment, Forest and Climate Change (MOEFCC) can be seen trying to dodge the bullet of accountability. News 18 reports that “The APPCB told the state committee [that] these permissions [consent for establishment and operation], under the Air Act and Water Act, were given as they are not linked to environmental clearance.” However, the state-level High Power Committee suggests that the APPCB should have consulted the center. It also added that while granting permissions under the Air Act and Water Act, the APPCB ought to take into account the residential areas located in the vicinity of red category industries. It is evident that the lack of accountability on the part of governments, state institutions, and public officials, as well as diverse private sector stakeholders, tends to magnify the material and human costs of disasters. What exacerbates the situation is that the roles and responsibilities between different levels of government (vertically) and across the various local actors (horizontally) are not always clear or monitored for Disaster Risk Reduction (DRR) to ensure an effective system of accountability. The Sendai Framework for Disaster Risk Reduction 2015-2030, adopted by the UN Member States in 2015, recognizes that the State has the primary role in reducing disaster risk. Arife Coskun warns that the involvement of multiple institutions and actors in DRR—including technical, political, administrative, national, local, formal, and informal—further diffuses the lines of accountability when faced with the consequences of various disaster risks, or the failure to reduce them. Given the multiplicity of actors involved in disaster risk governance, it is necessary to develop a comprehensive governance framework indicating the definitive roles and functions of government institutions, and the statutory obligations of different stakeholders. “While a comprehensive national DRR plan can do the above, new legislative enactments might be required to ensure legal enforceability of accountability obligations” (Amaratunga, Haigh, and Hettige, 2019).

The Importance of Categories: Tools of classification, Modes of Evasion

According to the Environmental Impact Assessment(EIA) notification (amendment) of 2006 under the Environment Protection Act of 1986, LG Chemicals India, which is part of the petrochemical industry, falls into the category ‘A’ and should ‘get’(seek) clearance from the MoEFCC every time they look to expand their plant or bring a change to their manufactured product, starting in November 2006. As per the EIA notification, all projects and activities are broadly categorized into two categories – Category A and Category B, based on the spatial extent of potential impacts on human health and natural and man-made resources. The categorization of industries has real implications for how their environmental impact is assessed and ultimately on how they will function. However, in this categorization, there is reasonable ambiguity. According to the notification, all Category A projects (with potentially significant impacts) are required to carry out an EIA and undertake a public hearing before an EC may be granted by the Union environment ministry. Category B projects (with potentially less significant impacts) are evaluated and given clearance by state-level authorities, the State Environment Impact Assessment Authority (SEIAA), and the State Expert Appraisal Committee (SEAC). Moreover, projects under Category B1 also require an EIA and public consultation, but those falling under B2 are exempted from the requirements of both EIA and public consultation. What is pertinent to the discussion here, as has been noted by the Expert Appraisal Committee, is that the company submitted its proposal for an EC to the State Level Environmental Impact Assessment Agency (SEIAA) on April 12, 2018, under the claims that it is a category B project, most likely in a bid to leverage the less stringent requirements of the category in question (Nutti, 2020).

Lack of Urgency and Intent

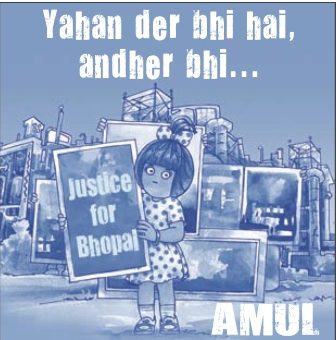

A satirical take on the procedural delays and lack of transparency in the institutional mechanisms of disaster prevention. It says “yahan der bhi hai, andher bhi” in Hindi, which roughly translates into “Justice delayed, Justice denied”. Source: Flickr- Amul on Bhopal Gas Tragedy & Indian Judicial Disaster

Another EIA notification released in 2017, lays down provisions for post-facto project clearance, which are reiterated in the Draft EIA notification 2020. This allows existing establishments to seek EC under the ‘violation category’ and is touted to bring more industries under the banner of compliance. It is interesting to note that only those establishments which have expanded their capacity or have brought about changes in the technology of production fall under the ‘violation category’ requiring post facto environmental clearance. This implies that factories operating without clearance and not fulfilling the expansion criteria get to carry on with their business as usual. Given the acknowledgment that a hazardous industry has been operational for a certain period, having flouted the requirements of environment clearance, it defies all logic that there is no provision in this ‘special’ category to assess the impact of unmonitored, unhindered industrial operation for many years, decades even. When LG polymers applied for an EC in 2017, it had already been operating without any such assessment for about 20 years, starting 1997, when the Korean giant LG Chemicals took over the reins from Hindustan Polymers. The sense of urgency that should accompany a request for a post-facto approval can be seen neither in the EIA requirements nor in the uptake and resolution of these requests by the MOEFCC, as is illustrated by the chronology of events in the LG polymers case.

The 2017 notification lays down a drawn-out process where an EIA evaluation of the company filing for clearance under the violation category is deemed necessary only after an appraisal committee gives it a green light to continue. This process involves a significant loss of time. This design itself ignores the urgency of the risk posed by dangerous industries such as the LG plant in question. Also, a part of the notification mentions that violations would warrant ‘action’ against the ‘project proponent’ by the respective State or State Pollution Control Board and that certificates of occupancy or operation will be withheld until the project is granted the environmental clearance. What is meant by ‘action’ to be taken by the State Pollution Control board is, at best, vague. In the case of Vizag, it was noted that even though the post-facto clearance of the LG plant was still underway, the APPCB still granted consent for operations in June 2018.

Further, it can be argued that in case of violations it would be prudent to factor in public consultation at this point, to take stock of the experiences of the ‘public’ with regards to the environmental and health effects of the plant. However, given that ‘public knowledge’ is often relegated to the domain of ‘lay perception’ and considered subordinate to expert assessment, such a proposition finds no place in the EIA notification. Rather, the 2020 Draft further exempts various categories from seeking public consultation at any stage whatsoever and instances of suspected ‘violations’ have to be reported either by a government authority or the developers themselves.

Not only are the experiences of the ‘publics’ excluded from the clearances granted under the ‘violations category,’ environmentalists and social activists have also pointed out the absence of any urban planning with regard to the location of the LG polymers plant in Vizag. The Hindu notes that the original Hindustan Polymers plant established in 1961 was located on the outskirts of the city. The village of R.R. Venkatapuram, although said to be sparsely populated, was in close proximity to it. Over the years, the residential pattern has overseen tremendous transformation. From being a remotely located village, R.R. Venkatapuram has turned into a bustling suburb, and over 40,000 people live within a 3-km radius of the plant. The flagrant disregard of land use considerations in the establishment of these plants can be understood using the concept of “socio-ecological classes”. Ramchandra Guha explains how a class known as “ecosystem people”— represented by the local populace of developing countries—is exposed to the toxic effects of hazardous plant operations. The class of Omnivores, such as the South Korean conglomerate LG, pockets the profit at the cost of the health and environment of the former while shifting those risks away from the affluent populations of their native countries. Over a period of about six decades, the threat of an impending disaster had been looming large over the day to day lives of the “ecosystem people.” It was only after the fallout on May 07, 2020, that the committee looking into the case pointed out the need for demarcating a buffer zone around industries listed under the red category prior to granting Consent for Establishment.

Through this discussion, we try to drive home the idea that the aftermath of this industrial catastrophe not only exposes the fissures in the existing regulatory system, it also underscores the importance of broadening the scope of the modes of inquiry into the causes of these disasters, bringing to the fore the social and epistemic allegiances of the various actors comprising the regulatory framework.

References:

Amaratunga, D., Haigh, R. and Hettige, S. (eds.) (2019) Accountability in the Context of Disaster Risk Governance; UNDRR. ISBN 978-1-86218-170-0

Bucchi, M., & Neresini, F. (2016). Science and Public Participation. In U. Felt, R. Fouché, C. A. Miller, & L. Smith-Doerr (Eds.). The Handbook of Science and Technology Studies. MIT Press.

Ghanekar, N. (2020, July 08). Vizag Gas Leak: Lack of Green Clearance from Centre Indirect Cause of Tragedy, Says State Govt Panel. News18 India. Retrieved from: news18.com

Guha, R., & Advani, R. (2006). How much should a person consume? Environmentalism in India and the United States. University of California Press.

Jasanoff, S. (2007) Bhopal’s trials of knowledge and ignorance. Isis 98(2): 344–350.

Nutti, S. (2020, May 9). LG Polymers had admitted in 2019 they were bound to pay 100% penalty for illegal operations. The Indian Express. Retrieved from https://www.newindianexpress.com/states/andhra-pradesh/2020/may/09/lg-polymers-had-admitted-in-2019-they-were-bound-to-pay-100-penalty-for-illegal-operations-2141138.html

Ottinger, G., Barandiaran, J., & Kimura, A. H. (2016). Environmental justice: knowledge, technology, and expertise. The Handbook of Science and Technology Studies, 1029-1057.

Ramanathan, S., Singh, D., & Yadav, N. K. (2020, May 8). The complete Story of Vizag gas leak. Down To Earth. Retrieved from: https://www.downtoearth.org.in/dte-infographics/vizag_gas_leak/index.html

Zinn, J. O. (2009). Introduction: The Contribution of Sociology to the Discourse on Risk and Uncertainty. In Social Theories of Risk and Uncertainty: An Introduction. Chichester: John Wiley & Sons (p.1-16).

4 Comments

An excellent article that discusses the real issues that like behind such human tragedies, that are completely avoidable. It is time that people work up and spoke out such issues….else we just live to see another similar disaster!! Great read!!

A very well written article, specially analysing the lapses from the company and check points for govenment authorities. Happy to see young people creating awareness and focusing on governance… hope people learn from these mistakes and prevent such mishappenings in the future.

This article is an interesting one and an eye opener. Kudos to the authors for the detailed research and insights.

Giving more insight into a tragedy that rocked the nation and getting into regulatory bodies for failure where many point to company and management.Thumbs up two brilliant minds to bring this up.